FAST DELIVERY | 14 DAY RETURNS | 200,000+ PRODUCTS | AUSTRALIAN OWNED & STOCKED

Menu

-

-

Furniture

-

Baby & Kids

-

Home & Garden

-

Rugs

-

Toys & Games

-

Appliances

-

KITCHEN APPLIANCES

- Air Fryers

- Food Cookers & Steamers

- Toasters

- Electric Kettles

- Microwaves

- Mixers

- Portable Cooktops

- Electric Juicers

- Blenders & Soup Makers

- Grills

- Meat Grinders & Mincers

- Food Dehydrators

- Deep Fryers

- Food Vacuum Sealers

- Food Processors

- Waffle & Pancake Makers

- Water & Ice Dispensers

- Water Filters & Coolers

- Kitchen Appliance Accessories

- Ice Makers

- COFFEE MAKERS

- VACUUM CLEANERS

- FRIDGES & FREEZERS

- HEATERS

- AIR CONDITIONERS

- FANS

- AIR TREATMENT

- COOKTOPS

- RANGEHOODS

- OVENS

- IRONING APPLIANCES

-

KITCHEN APPLIANCES

-

Sports & Outdoors

-

Electronics

-

Tools & Equipment

-

Christmas

-

- Login

FAST DELIVERY | 14 DAY RETURNS | 200,000+ PRODUCTS | AUSTRALIAN OWNED & STOCKED

3D Printing

3D Printing – High-Quality Printers & Accessories | Bargain Avenue

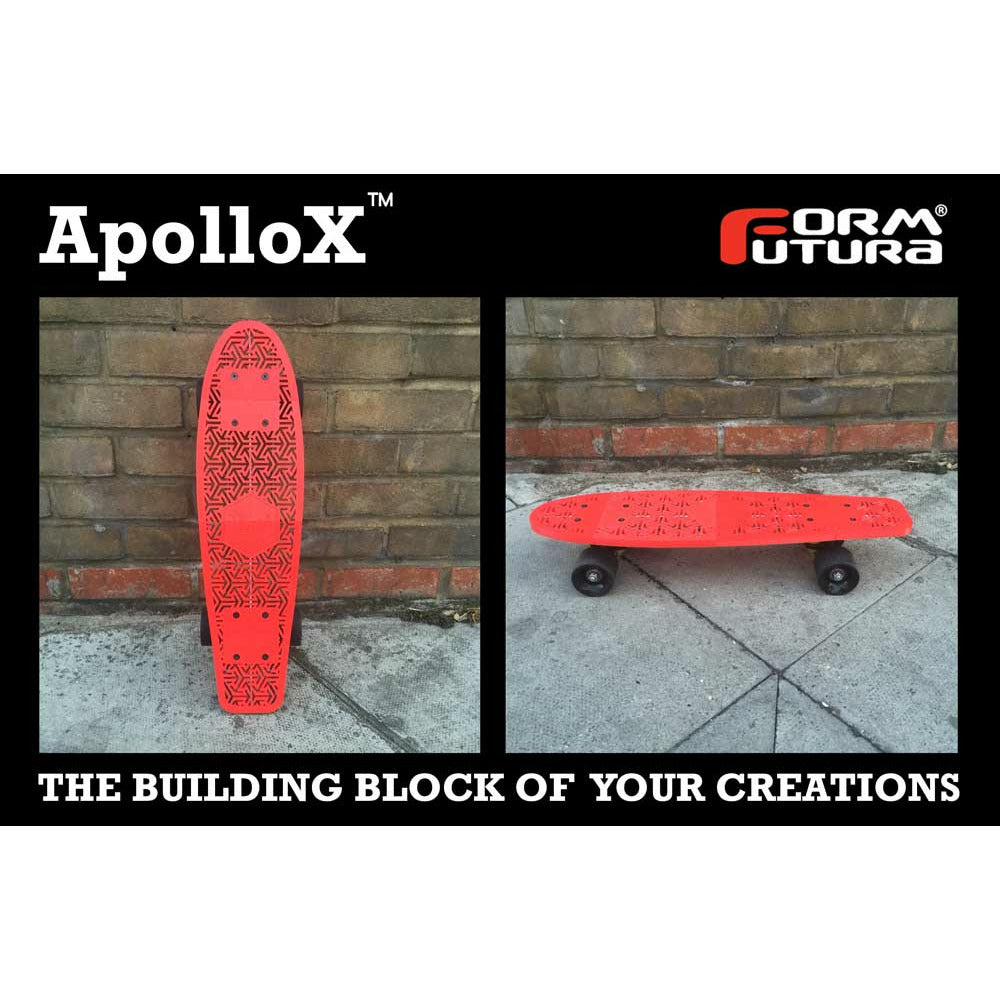

Unlock endless creativity with our 3D printing collection at Bargain Avenue! Whether you're a hobbyist, professional, or educator, we offer high-quality 3D printers, filaments, and accessories to bring your ideas to life. From precision printing to durable materials, we have everything you need to create stunning 3D models with ease.

Why Shop 3D Printing at Bargain Avenue?

✔ Wide Selection – Choose from top-quality 3D printers and accessories.

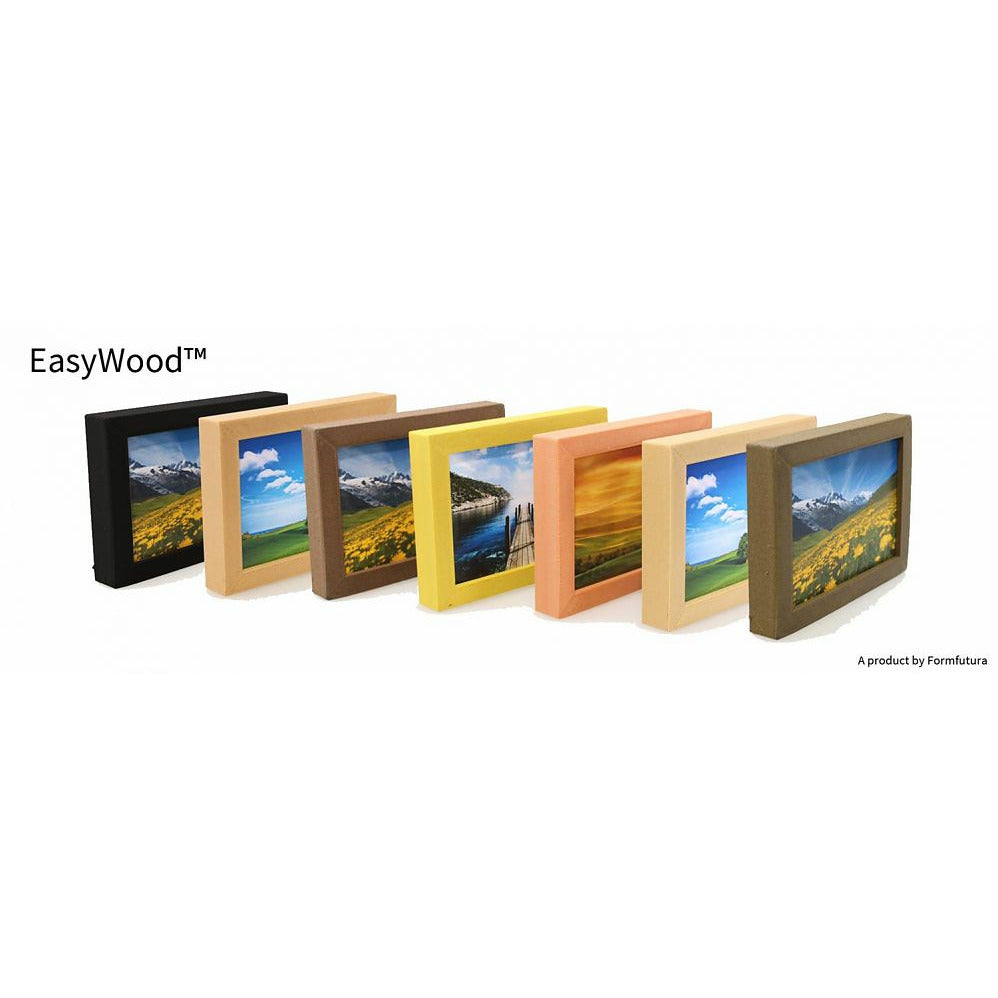

✔ High-Performance Filaments – Durable materials for detailed prints.

✔ Perfect for All Levels – Ideal for beginners, enthusiasts, and professionals.

✔ Reliable & Affordable – Get premium products at unbeatable prices.

✔ Australian Owned & Stocked – Quality products, ready to ship.

✔ Flexible Payments – Pay with Afterpay, Zip, or PayPal.

✔ Free Delivery – Available on eligible items.

Start your 3D printing journey today with Bargain Avenue. Shop now and bring your ideas to life!